In the ever-evolving landscape of transportation, innovation plays a pivotal role in shaping the efficiency and sustainability of commercial vehicles. Among the many advancements, the integration of aluminum has emerged as a transformative force. With its lightweight yet sturdy properties, aluminum has gained prominence as a game-changer in the design and manufacturing of commercial vehicles, ushering in a new era of performance, fuel efficiency, and environmental responsibility.

The commercial vehicle sector encompasses a wide range of vehicles, including trucks, buses, vans, and trailers, all of which are vital components of global logistics and trade networks. Here are two types of commercial vehicles. We Henan Wanda can supply the aluminum sheet and aluminum coil for making them.

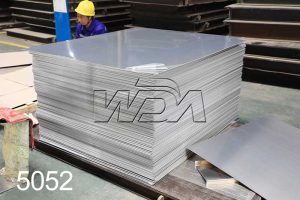

For this kind of bus, our 5052 aluminum sheet is used for parts like aluminum shell for air conditioner on bus roof, aluminum skin for bus roof, aluminum luggage trunk cover etc.

Aluminum shell for air conditjoner on bus roof, Aluminum skin for bus roof, aluminumluggage trunk cover and aluminum back engine hood can all use 5052 alloy. The alumnum allov used for the whole car body,in lightweight, corrosion resistance. sealingperformance, sense of aesthetic, security, service life, etc, is superior to the steeltructure. which is the better choice for car manufacturing.

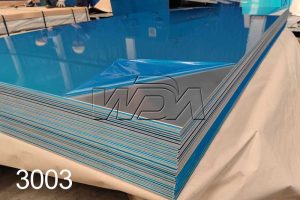

For this kind of bus, our 5052 aluminum sheet is used for parts like oil tank and pedal. The 5083 aluminum plate is used for gas storage cylinder.

It has features of trong corrosion resistance, strong collision resistance and endergonic performance; for checkered plate, it has high coefficient of slippery resistance and wear resistance, long service life, and light weight, which conforms to the requirements of automotive lightweight.

Traditionally, these vehicles were primarily constructed using steel due to its strength and durability. However, this came at the cost of increased weight, subsequently leading to reduced fuel efficiency and higher emissions. As the world became increasingly conscious of environmental concerns and stringent regulations, manufacturers sought alternatives that would simultaneously address performance and sustainability.

This is where aluminum comes into the picture. Aluminum is renowned for its unique combination of low density and high strength, making it an ideal material for reducing the overall weight of commercial vehicles without compromising on structural integrity. By replacing steel components with aluminum, manufacturers can significantly decrease the vehicle’s weight, which in turn enhances fuel efficiency and reduces carbon emissions. In an industry where even a small improvement in fuel efficiency can result in substantial cost savings and environmental benefits, aluminum’s impact is undeniable.

One of the most noteworthy advantages of aluminum in commercial vehicles is its contribution to payload capacity. By shedding excess weight, vehicles can carry larger payloads, translating to greater economic efficiency and fewer trips required to transport the same amount of goods. This not only reduces operational costs but also contributes to alleviating road congestion and minimizing the wear and tear on infrastructure. Additionally, the enhanced durability of aluminum against corrosion ensures that vehicles have a longer lifespan, reducing the frequency of replacements and conserving resources.

Furthermore, aluminum’s malleability opens the door to innovative designs that were previously impractical due to the limitations of traditional materials. Manufacturers can create aerodynamic shapes and contours that reduce drag, further improving fuel efficiency. This flexibility in design also allows for more creative and ergonomic interiors, enhancing the overall driving experience for operators and passengers alike.

While aluminum’s benefits are evident, its adoption in the commercial vehicle industry has not been without challenges. One of the primary concerns has been the initial cost of transitioning from steel-based manufacturing processes to those involving aluminum. However, this investment is increasingly viewed as a strategic move, considering the long-term gains in terms of operational savings and environmental stewardship. Manufacturers have also addressed concerns about the recyclability of aluminum, highlighting its status as one of the most recyclable materials on the planet. This not only aligns with sustainability goals but also reduces the reliance on raw materials.

In recent years, several prominent commercial vehicle manufacturers have embraced aluminum as a cornerstone of their product development strategies. From lightweight trailers that optimize freight transportation to buses with improved fuel economy and reduced emissions, aluminum’s presence is evident across the industry.

In conclusion, the integration of aluminum in the manufacturing of commercial vehicles marks a significant shift towards efficiency, sustainability, and innovation. By reducing vehicle weight, enhancing fuel efficiency, and promoting creative design solutions, aluminum has positioned itself as a catalyst for positive change in an industry vital to global economies. As technology continues to advance, the potential for aluminum’s role to expand and evolve within the commercial vehicle sector is both promising and exciting. With each aluminum-laden vehicle that hits the road, the transportation industry takes a step closer to a more sustainable and prosperous future.