Aluminum for Power Battery Case

- Thickness: 0.8mm-3mm

- Width: Under 1600mm

- Length:Under 11000mm(11m) or by coil

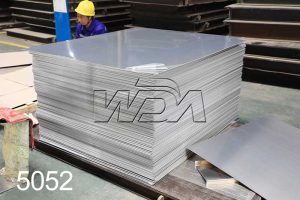

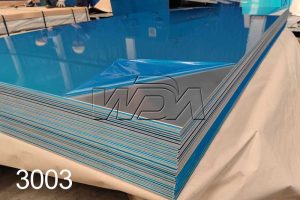

- Alloy: 3003, 5052, 6061, 5083, 3004

- Email: wandaaluminumsheet@gmail.com

- Tel & WhatsApp: +8613619844700

When selecting an aluminum alloy for a power battery case, several factors need to be considered, including mechanical strength, thermal conductivity, corrosion resistance, formability, and manufacturability. The choice of alloy will depend on the specific requirements of the battery case design, such as size, shape, weight, and intended use. Here are a few aluminum alloys commonly considered for power battery cases:

- Aluminum Alloy 6061 (T6): This alloy is widely used for its combination of strength, machinability, and corrosion resistance. It’s often chosen for applications where structural integrity is important. The T6 temper provides enhanced strength and hardness.

- Aluminum Alloy 5052: With good corrosion resistance and moderate strength, 5052 is commonly used in marine and outdoor applications. It can be a suitable choice if the battery case will be exposed to environmental elements.

- Aluminum Alloy 6063 (T5 or T6): Similar to 6061, 6063 is often used for extrusions and structural components. If the battery case requires intricate shapes or complex cross-sections, this alloy’s extrudability can be beneficial.

- Aluminum Alloy 5083: Known for its excellent corrosion resistance and high strength, 5083 is suitable for battery cases that will be subjected to challenging environments.

- Aluminum Alloy 3003: This alloy offers good formability and moderate strength. It’s often chosen for non-structural components and enclosures.

- Aluminum Alloy 6060: Similar to 6063, 6060 is extrusion-friendly and can be used for cases with complex shapes and profiles.

- Aluminum Alloy 3004: With good formability and corrosion resistance, 3004 is suitable for battery cases that require deep drawing or forming.

- Aluminum Alloy 5086: This alloy is used in applications requiring high corrosion resistance, particularly in marine environments. It’s a strong and lightweight option.

- Aluminum Alloy 3005: This alloy combines good formability with moderate strength and corrosion resistance, making it suitable for various battery case components.

- Aluminum Alloy 5005: Similar to 5052, 5005 offers good corrosion resistance and weldability. It can be chosen based on specific design requirements.

When selecting an alloy, consider factors like the battery case’s intended environment, whether it will be subjected to temperature variations or corrosive substances, and the desired level of mechanical protection for the batteries. Collaborating with materials experts and manufacturers with experience in battery housing design can help you make an informed decision based on your specific needs. If you need these aluminum sheet for your project, just email me wandaaluminumsheet@gmail.com or whatsapp me +8613619844700.