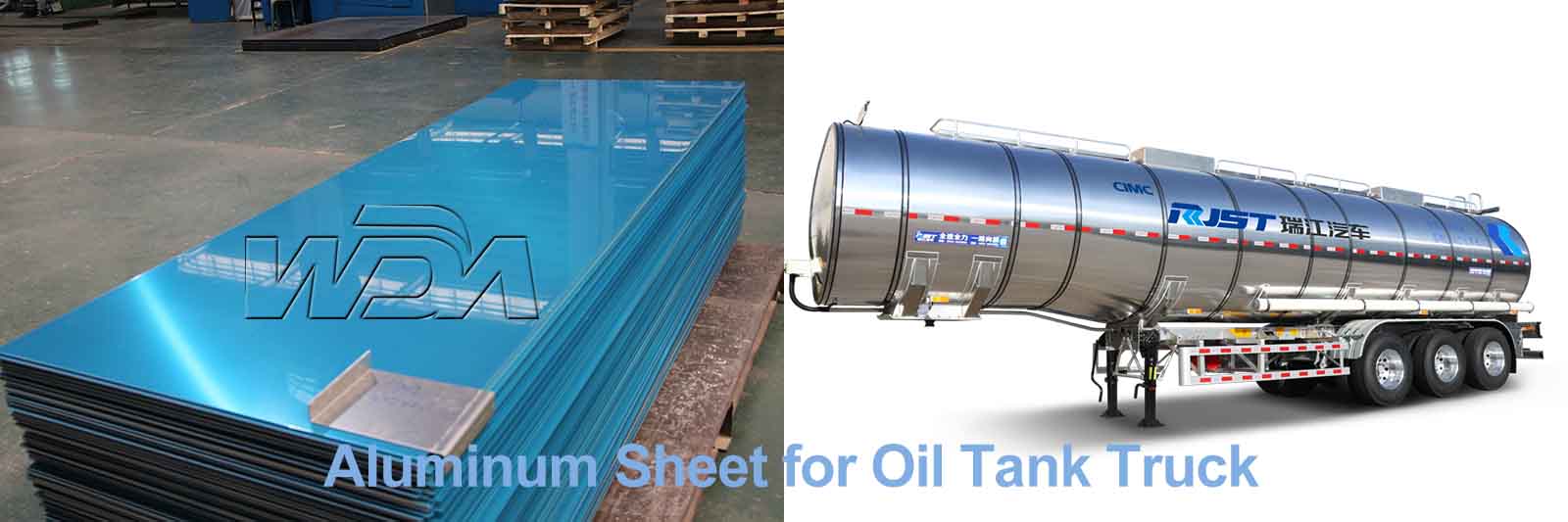

Aluminum for Oil Tank Truck

- Thickness: 3.0mm-6.0mm

- Width: Under 2250mm

- Length:Under 11000mm(11m) or by coil

- Email: wandaaluminumsheet@gmail.com

- Tel & WhatsApp: +8613619844700

The aluminum alloy used for oil tank trucks can vary depending on the specific requirements of the tank and its intended use. Some of the commonly used aluminum alloys for oil tank trucks include:

- 5083 Aluminum Alloy – This alloy is often used for the construction of oil tank trucks because of its excellent corrosion resistance and high strength. It is also highly resistant to stress cracking and has good weldability, making it easy to manufacture and repair.

- 5454 Aluminum Alloy – Another popular choice for oil tank trucks is the 5454 aluminum alloy. This alloy has good corrosion resistance and high strength, as well as excellent weldability and formability.

- 6061 Aluminum Alloy – While not as commonly used as 5083 or 5454, the 6061 aluminum alloy can also be used for oil tank trucks. This alloy has good corrosion resistance and high strength, as well as good weldability and formability. However, it is not as resistant to stress cracking as 5083 or 5454.

When selecting an aluminum alloy for an oil tank truck, it is important to consider factors such as the type of cargo being transported, the conditions in which the tank will be used, and the required strength and durability of the tank. It is also important to ensure that the alloy selected meets any relevant industry standards and regulations.

Aluminum for Oil Tank Truck: Benefits and Advantages

In the transportation industry, the safety of both the driver and the cargo is of utmost importance. This is especially true for the transportation of hazardous materials, such as oil and gasoline. Oil tank trucks are a common sight on our roads, and the materials used to manufacture these trucks can greatly impact their safety and effectiveness.

In recent years, there has been a shift towards using aluminum for the construction of oil tank trucks. This shift has been driven by several factors, including the numerous advantages that aluminum provides over traditional materials like steel. In this article, we will explore the benefits and advantages of using aluminum for oil tank trucks.

Lightweight and Durable

One of the primary advantages of using aluminum for oil tank trucks is its lightweight and durable nature. Aluminum is approximately one-third the weight of steel, which means that aluminum tank trucks can carry more cargo while also using less fuel. This makes aluminum tank trucks more efficient and cost-effective than their steel counterparts.

In addition to being lightweight, aluminum is also extremely durable. It has a high strength-to-weight ratio, which means that it can withstand a great deal of stress and strain without deforming or breaking. This makes aluminum tank trucks less susceptible to damage in the event of an accident, which can help to protect the driver and the cargo.

Corrosion-Resistant

Another advantage of using aluminum for oil tank trucks is its corrosion-resistant properties. When exposed to the elements, steel can rust and corrode over time, which can weaken the structure of the tank and make it more prone to leaks and failures. Aluminum, on the other hand, is naturally resistant to corrosion and rust, which makes it an ideal material for the transportation of hazardous materials like oil and gasoline.

Aluminum also has a natural oxide layer that forms on its surface, which acts as a barrier to protect against corrosion. This layer can be further enhanced through the use of specialized coatings, which can help to extend the lifespan of the tank and reduce maintenance costs.

Improved Fuel Efficiency

As mentioned earlier, aluminum tank trucks are significantly lighter than their steel counterparts. This means that they require less fuel to operate, which can help to reduce fuel costs and improve overall fuel efficiency. In addition to being more fuel-efficient, aluminum tanks also have the potential to improve aerodynamics, which can further enhance fuel efficiency.

Improved Safety

Safety is a top priority when it comes to the transportation of hazardous materials like oil and gasoline. Aluminum tank trucks provide several safety benefits over traditional steel tanks. For example, aluminum tanks are less prone to punctures and leaks, which can help to prevent spills and accidents. They are also less likely to deform or rupture in the event of a collision, which can help to protect the driver and the cargo.

In addition to these benefits, aluminum tanks also provide improved fire resistance. Aluminum has a high melting point, which means that it can withstand higher temperatures than steel before melting. This can help to prevent the tank from rupturing or exploding in the event of a fire, which can greatly reduce the risk of injury or death.

In conclusion, the benefits and advantages of using aluminum for oil tank trucks are numerous. Aluminum is lightweight, durable, corrosion-resistant, fuel-efficient, safe, and environmentally-friendly. If you’re looking for aluminum for oil tank truck, just email us: wandaaluminumsheet@gmail.com or WhatsApp us: +8613619844700.