Introduction

When it comes to metal fabrication and construction projects, aluminum sheets are widely used for their versatility and durability. However, understanding the factors that influence aluminum sheet prices can help you make informed decisions for your projects. In this comprehensive guide, we will explore the various factors that affect aluminum sheet prices and provide cost-effective solutions to help you optimize your budget.

-

Factors Affecting Aluminum Sheet Prices

Several factors contribute to the pricing of aluminum sheets. Firstly, the global supply and demand dynamics play a significant role. If the demand for aluminum exceeds its supply, prices tend to rise. Additionally, the cost of raw materials, such as bauxite and energy, influences the overall pricing. Market conditions, trade policies, transportation costs, and fluctuations in currency exchange rates can also impact aluminum sheet prices.

-

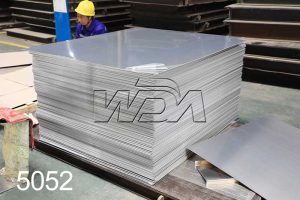

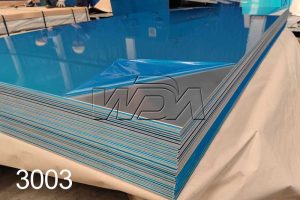

Grade and Alloy Composition

The grade and alloy composition of aluminum sheets directly affect their price. Aluminum alloys are engineered to possess specific properties, such as strength, corrosion resistance, and formability, which determine their usability in different applications. The more specialized the alloy composition, the higher the price. Common alloy series like 1xxx, 3xxx, and 5xxx are often more affordable, while high-performance series like 6xxx and 7xxx might be pricier due to their superior properties.

-

Sheet Thickness and Size

Aluminum sheet prices also depend on their thickness and size. Thicker sheets generally cost more due to the increased amount of raw material required for production. Similarly, larger sheet sizes may be more expensive due to handling and transportation challenges. It’s important to evaluate your project’s requirements carefully to determine the optimal thickness and size of aluminum sheets needed to balance performance and cost.

-

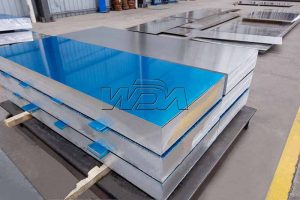

Surface Finish and Coatings

Surface finish and coatings can significantly impact the price of aluminum sheets. Smooth, mill-finished sheets are usually more economical, while specialty finishes like brushed, anodized, or painted surfaces can increase the price due to additional processing steps and materials. Similarly, applying protective coatings, such as polyester or PVDF, to enhance corrosion resistance and aesthetics can also contribute to the overall cost.

-

Cost-Effective Solutions

To optimize your budget while using aluminum sheets, consider the following cost-effective solutions:

- Bulk purchasing: Buying in larger quantities can often lead to volume discounts.

- Standard alloys and sizes: Choosing commonly available alloys and standard sizes can help reduce costs.

- Strategic sourcing: Research and compare prices from multiple suppliers to find the most competitive offers.

- Recycling: Consider using recycled aluminum sheets, which are often more cost-effective and environmentally friendly.

- Optimization: Minimize waste by accurately estimating your project’s aluminum sheet requirements to avoid unnecessary expenses.

Conclusion

Understanding the factors that influence aluminum sheet prices empowers you to make informed decisions for your projects. By considering factors such as grade, alloy composition, thickness, size, surface finish, and coatings, as well as implementing cost-effective solutions, you can strike the right balance between quality and affordability while utilizing aluminum sheets for your applications. If you are looking for aluminum sheet price, email me wandaaluminumsheet@gmail.com or whatsapp me +8613619844700.