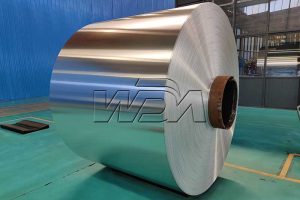

Aluminum coil is commonly used for making the body part of a can. The aluminum coil is typically made from 3004 or 3104 alloy, which is a type of aluminum alloy that contains manganese as its primary alloying element.

The aluminum coil is first cleaned and coated with a thin layer of lubricant to prevent scratching or damage during the stamping process. The coil is then fed through a stamping machine that cuts it into flat sheets and shapes them into cups.

The cups are then washed and treated with a chemical solution to remove any remaining oils or lubricants. The cups are also etched to create a rough surface that helps the paint adhere to the aluminum.

The cups are then coated with a layer of paint and cured in an oven to harden the paint. The painted cups are then formed into cans using a series of processes, including trimming, seaming, and necking.

Aluminum is a popular choice for making cans because it is lightweight, strong, and resistant to corrosion. It also can be easily recycled, making it an environmentally friendly option.

As a supplier of aluminum coil for cans, Henan Wanda has 20 years experience. We have lots of can factory customers. They are pleased at the aluminum coil we supplied. If you are also interested in aluminum coil for cans, just contact me by email wandaaluminumsheet@gmail.com or WhatsApp me +86 13619844700.