Introduction

Malleable aluminum sheets have emerged as a versatile solution for various industries due to their exceptional properties. From automotive and construction to aerospace and packaging, aluminum sheets offer a multitude of advantages. This article explores the benefits and applications of malleable aluminum sheets, highlighting their unique characteristics and why they are a preferred choice in today’s market.

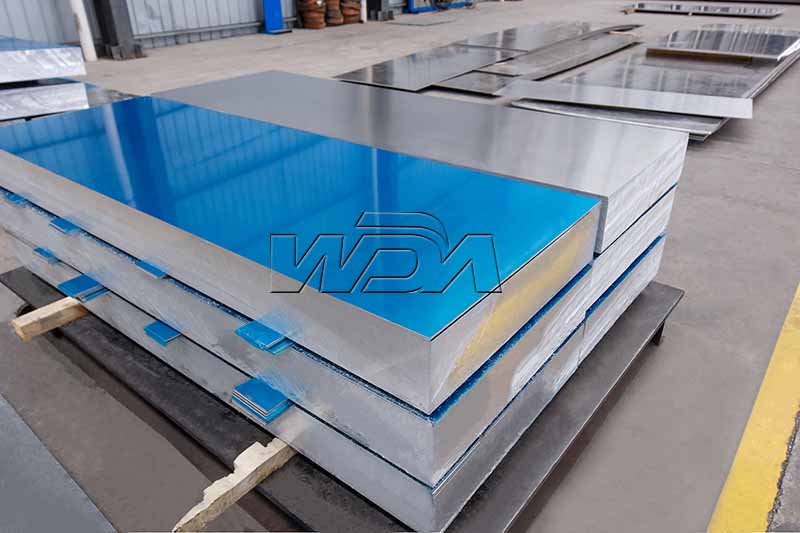

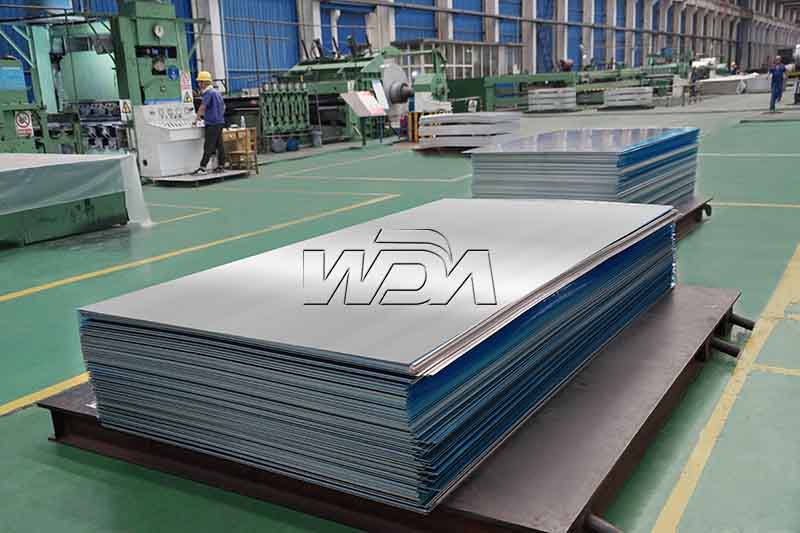

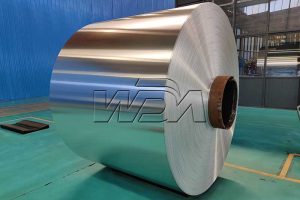

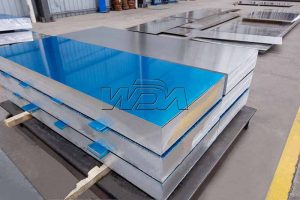

Understanding Malleable Aluminum Sheets

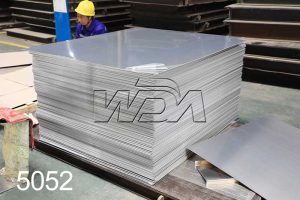

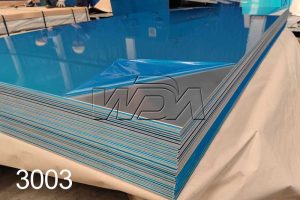

Malleable aluminum sheets are thin, flat pieces of aluminum that can be easily bent, shaped, and formed without cracking or breaking. They are typically manufactured using pure aluminum or aluminum alloys, making them lightweight, corrosion-resistant, and highly flexible. The malleability of aluminum sheets allows them to be manipulated into various forms, making them an ideal material for numerous applications.

Applications of Malleable Aluminum Sheets

- Automotive Industry: Malleable aluminum sheets are widely used in automobile manufacturing due to their excellent strength-to-weight ratio. They are used in body panels, hoods, doors, and other components, reducing the overall weight of the vehicle and enhancing fuel efficiency.

- Construction Sector: Aluminum sheets find extensive applications in construction projects. They are used for roofing, cladding, siding, and window frames, offering durability, resistance to weathering, and ease of installation.

- Aerospace and Aviation: Malleable aluminum sheets are essential in the aerospace industry. They are used in aircraft structures, wings, fuselages, and interior components, providing high strength, low density, and resistance to corrosion.

- Packaging Industry: Aluminum sheets are widely used in packaging applications due to their exceptional barrier properties. They help preserve the quality and freshness of food and beverages, while also being lightweight and recyclable.

Benefits of Malleable Aluminum Sheets

- Lightweight and Durable: Aluminum sheets are known for their low density, making them lightweight without compromising strength. This property is particularly advantageous in industries such as automotive and aerospace, where weight reduction is critical for performance and fuel efficiency.

- Corrosion Resistance: Aluminum naturally forms a thin oxide layer on its surface, providing excellent corrosion resistance. This makes malleable aluminum sheets highly durable and long-lasting, even in harsh environments.

- Excellent Formability: The malleability of aluminum sheets allows for easy shaping, bending, and forming. This characteristic enables manufacturers to create complex designs and customized products, offering flexibility and versatility in various applications.

- Recyclability: Aluminum is one of the most recyclable materials on the planet. Malleable aluminum sheets can be recycled repeatedly without losing their properties, making them an environmentally friendly choice.

Conclusion

Malleable aluminum sheets have become a preferred material for numerous industries due to their exceptional properties and versatility. Their lightweight nature, durability, corrosion resistance, and excellent formability make them ideal for applications ranging from automotive and construction to aerospace and packaging. Additionally, the recyclability of aluminum sheets contributes to their sustainability and environmental benefits. As industries continue to seek innovative solutions, malleable aluminum sheets will undoubtedly remain a key component in meeting the demands of modern manufacturing processes. Whether it’s for enhancing fuel efficiency, creating aesthetically pleasing designs, or ensuring product integrity, malleable aluminum sheets offer a host of advantages that make them a smart choice for diverse industries. If you are looking for malleable aluminum sheets, just email me wandaaluminumsheet@gmail.com or whatsapp me +8613619844700 any time. I can send free quotation and more information to you for a reference.