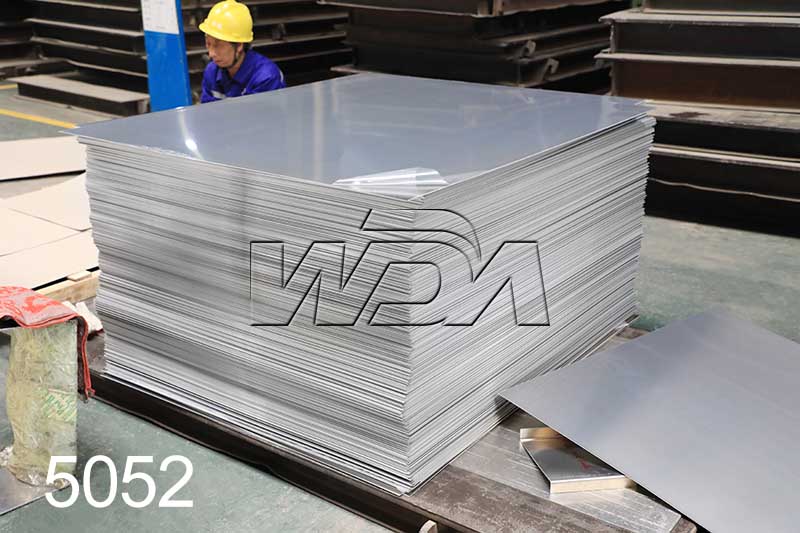

Aluminium 5083 and 5052 are two of the most commonly used aluminum alloys, especially in marine and industrial applications. Although they have similar properties, there are some key differences that set them apart.

Chemical Composition:

The main difference between the two alloys lies in their chemical composition. Aluminium 5052 is composed of magnesium as its primary alloying element, while Aluminium 5083 contains a higher amount of magnesium, as well as small amounts of chromium and manganese. This difference in composition makes 5083 alloy more resistant to corrosion than 5052.

Strength and Formability:

In terms of strength, Aluminium 5083 is considered to be stronger than 5052. It has a higher tensile strength and a better resistance to fracture, which makes it suitable for applications that require high strength and durability, such as marine and aerospace industries. On the other hand, Aluminium 5052 is known for its excellent formability, making it a popular choice for applications that require complex shapes and designs.

Weldability:

Both Aluminium 5083 and 5052 are considered to be highly weldable, but they differ in the types of welding processes used. Aluminium 5083 is commonly welded using the TIG and MIG welding processes, while Aluminium 5052 can be welded using all standard welding processes, including TIG, MIG, and spot welding.

Corrosion Resistance:

Aluminium 5083 has a higher resistance to corrosion than Aluminium 5052, which makes it a better choice for marine applications. It is particularly resistant to saltwater corrosion and is often used in shipbuilding and other marine applications. Aluminium 5052, on the other hand, is more susceptible to corrosion but is still suitable for many industrial applications.

Price:

The cost of Aluminium 5083 is typically higher than that of Aluminium 5052 due to its higher magnesium content and better corrosion resistance. However, the exact cost will depend on the size and quantity of the material purchased, as well as the supplier.

In conclusion, Aluminium 5083 and 5052 are both popular aluminum alloys with their unique properties and characteristics. The choice between the two will depend on the specific application and requirements, with Aluminium 5083 being a better choice for high-strength, corrosive-resistant applications, and Aluminium 5052 being more suitable for applications that require formability and cost-effectiveness.